Tel : +8617720928626 Email : sales@hoozoe.com

|

What Are You Looking For?

What Are You Looking For?

Tel : +8617720928626 Email : sales@hoozoe.com

Fujian Hoozoe Optoelectronics Co., Ltd. is a leading high-tech enterprise dedicated to the R&D, manufacturing, and sales of a comprehensive range of professional LED display screens. We are more than a supplier; we are a solutions partner, providing end-to-end support for diverse customer needs and applications.

Our solid foundation is reflected in our scale and commitment: a registered capital of 186.6 million RMB, a workforce of over 800 dedicated employees, and a modern production facility spanning 120,000 square meters. Driving our innovation is a professional technical team that makes up 12% of our staff, supported by an excellent sales network and a complete after-sales service system, ensuring quality from concept to long-term operation.

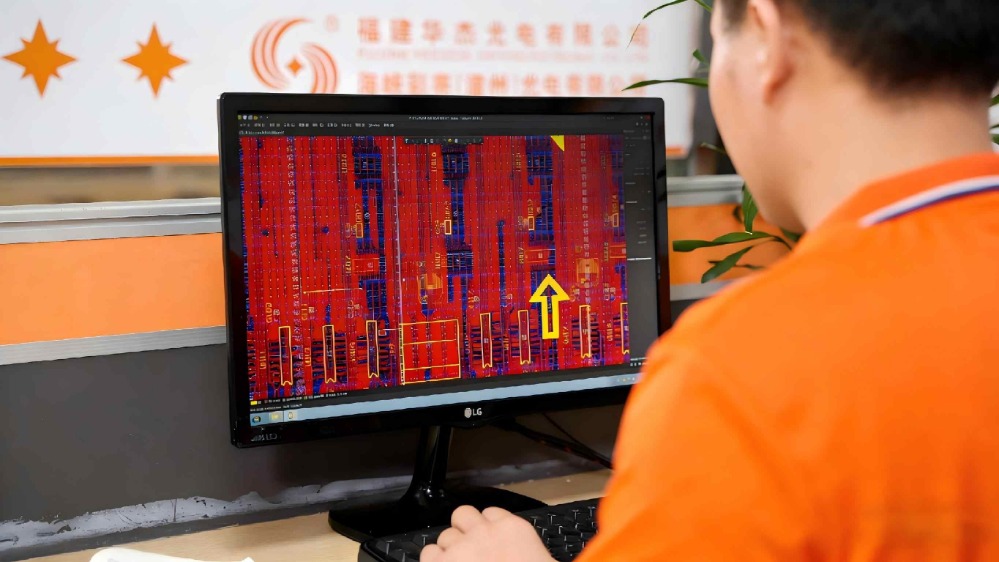

At the heart of every reliable display we deliver is a meticulously controlled manufacturing process. Below is an overview of the core production stages that define the quality and performance of Hoozoe LED modules.

Our manufacturing philosophy ensures that every module, destined for either indoor refinement or outdoor resilience, is built on a foundation of precision and rigorous quality control. The entire process is a seamless integration of advanced technology and meticulous craftsmanship, structured into four definitive stages.

This initial phase constructs the module's reliable "nervous system," common to all our products.

Key Steps: The process begins with traceability labeling on each PCB. A stencil printer then precisely applies solder paste to the Integrated Circuit (IC) pads. Next, high-speed SMT (Surface Mount Technology) machines accurately place micro-components like resistors, capacitors, and driver ICs. The assembled board travels through a reflow oven, where the paste melts and solidifies to form permanent electrical bonds. Finally, an AOI (Automated Optical Inspection) system performs a critical scan to detect any soldering or placement defects.

This step imbues the module with its core visual capability, determining ultimate display performance.

Key Steps: A specialized stencil applies solder paste to the LED mounting pads. A high-precision die bonder then places thousands of microscopic LED chips onto their exact positions. A second controlled reflow soldering process permanently attaches the chips. This stage is paramount for achieving the exceptional brightness uniformity, color accuracy, and longevity that define Hoozoe displays.

Here, the production path diverges to tailor each module for its specific operational environment, ensuring optimal performance and durability.

A. For Outdoor Modules: Engineered for Endurance

The focus shifts to building an impenetrable defense against the elements.

Protective Coating: A conformal coating is sprayed onto the assembly, providing a protective barrier against moisture, corrosion, and dust.

Sealing & Housing: After the coating is cured, waterproof sealant is dispensed along all seams. The module is then housed in a structurally robust, weatherproof cabinet designed for superior heat dissipation and physical protection.

B. For Indoor Modules: Optimized for Visual Fidelity

The process prioritizes enhancing the viewer's visual experience in controlled environments.

Visual Enhancement: The key step is installing a precision optical mask. This component is critical for enhancing image contrast, reducing glare, and defining sharp pixel boundaries for a crystal-clear picture.

Final Assembly: A standard bottom shell is installed to complete the module assembly.

Every module must pass our final, rigorous validation to earn the Hoozoe seal of approval.

Functional Testing: Each unit undergoes comprehensive power-on testing to verify full functionality, checking for parameters like brightness, color consistency, and the absence of dead pixels.

Aging for Reliability: To ensure long-term stability, modules are subjected to a burn-in aging test in a climate-controlled chamber (typically 45-55°C, 24-72 hours). This accelerated stress test simulates extended use and eliminates potential early-life failures.

System Assembly: Approved modules are seamlessly spliced into larger display units using precision connectors. The entire assembly is then calibrated as one system to guarantee perfect color uniformity and a seamless, gap-free viewing experience.

This disciplined, stage-gated manufacturing process is the backbone of our promise. It translates into tangible benefits for our clients: unmatched visual consistency, proven durability for challenging environments, and exceptional long-term value—from a single module to a grand video wall installation.

Leave A Message

Scan to Wechat :

Scan to WhatsApp :